Multi Stage Correction

When the enquiry came through for a Single Stage machine polish on a 911 the last thing I expected to arrive was a French Racing Blue Jaguar XF-RS. In the short time between arranging the initial inspection and bringing the car to see me the client had sold the Porsche and replaced it for this rather shouty V8 Powerhouse.

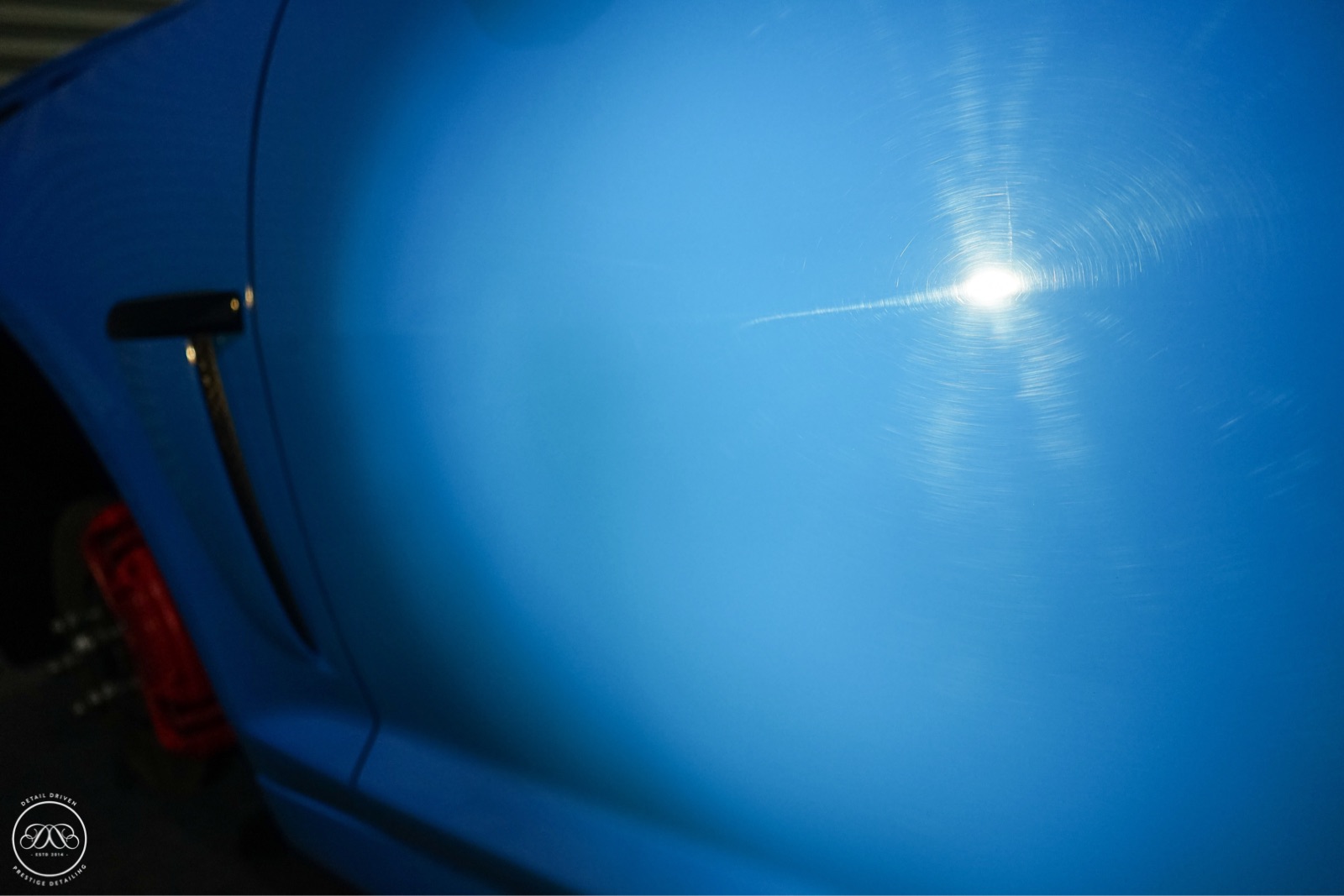

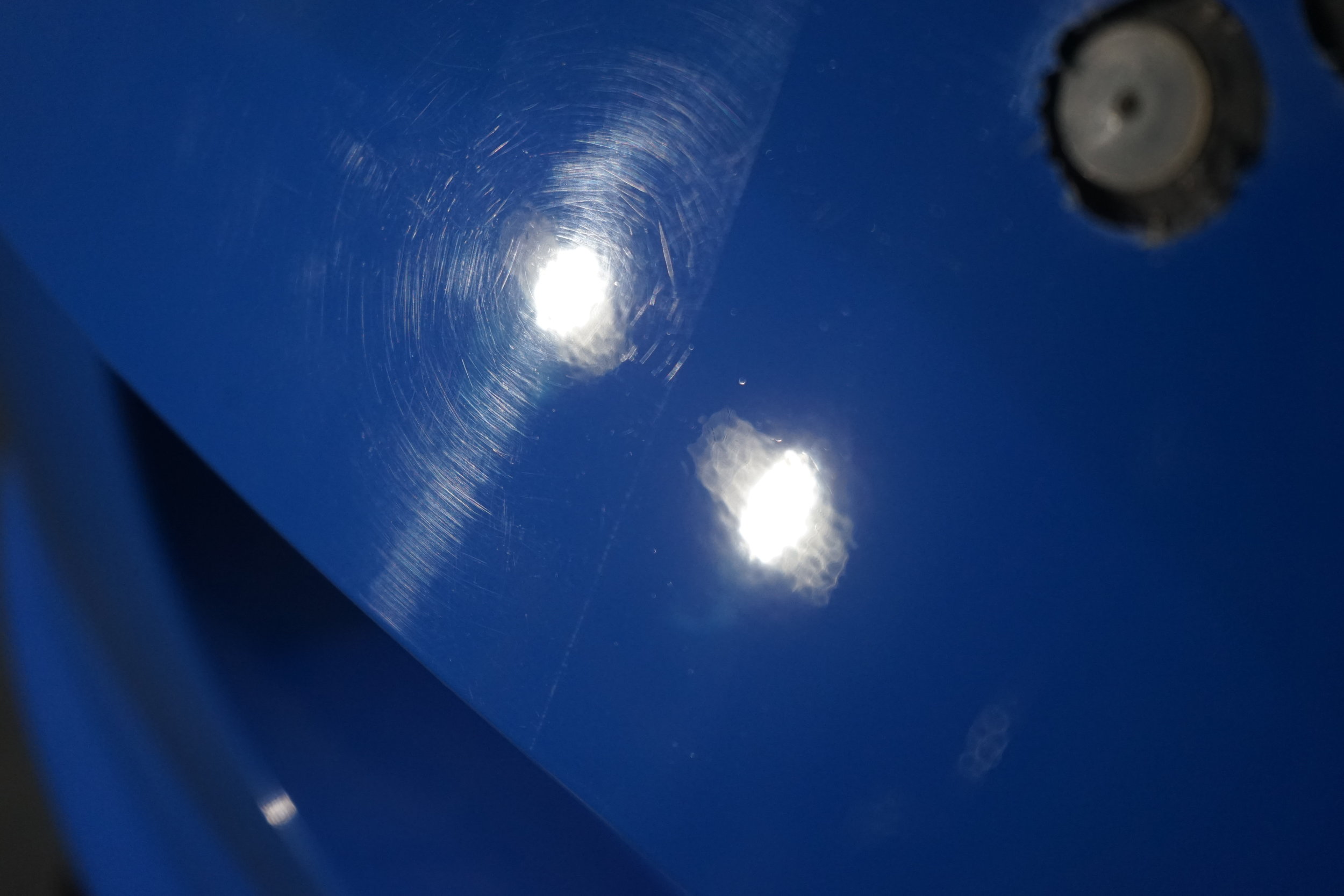

During it's initial inspection it was quickly evident the bodywork and exterior in general had been through a lot and it was going to take some serious work to get it up to scratch. A solid pastel blue French Racing Blue is an individual colour rarely found on many other Jaguars. 14 weeks later the car arrived onsite and I was relishing at the opportunity to transform such an iconic car for Jaguar.

The RS received the usual treatment outside a thorough decontamination and deep clean prior to the commencement of any machine work. These stages always reveal the true story behind every car and the true level of the task ahead. Booked for a multi stage correction detail I knew I had my work cut out but I wasn't prepared for some of the discoveries I made with the bodywork and wheels. Once inside the car was raised up and the wheels removed. Once I had the wheels off I was able to see the the terrible state they were in, neither me or the client were expecting me to find the nasty smart repairs on the wheels or the heaps of overspray in the barrels so after short discussions with my Wheel guy and the client all four wheels were sent off for full refurbishment while the car was with me. The discoveries didn't end there, the nearside had seen its fair share of repairs, the worst being the rear quarter which left a lot to be desired for. After completing the full initial assessment, depth readings and inspection delicate surfaces were taped and the initial cutting stage of machine polishing commenced.

In total I spent nearly three days cutting, being a solid paint French Racing blue was a super super soft paint to work with so patience was key. Go in too heavy and the paint micro marred, go in too light and I'd have been there all year. It was about finding a happy medium but the result of that is extended cutting stages as you can't go in with anything too agressive. The upside to this is that very little refining is required as I took my time with cutting very few defects were inflicted by the initial stage. The cutting stages were followed by a refining and finishing stage in order to ensure the striking blue was finished to the highest possible level adding a deep rich gloss and a very sharp crisp finish. In total I spent five long days cutting and refining the paintwork in order to reach a finish I deemed more than acceptable. Door shuts, boot shuts and the engine bay all received some level of polishing to ensure the highest possible finish throughout the vehicle. With final wipe down complete the first stage of coatings got underway with the base layer of GTechniq CS Light applied and left to cure overnight before returning in the morning to apply the top layer of Gtechniq EXO v3. At this point the wheels returned and the coating of the glass and wheels were complete and the end was finally in sight. I tend to spend in the region of a day completing all the final touches once all the coatings are applied. This allows me to work around the vehicle meticulously dressing the engine bay, polishing exhausts, dressing arches and tyres and chasing the level of perfection I pursue.

On the final day the wheels were returned and coated. The wheels unfortunately had seen an extremely hard life. Upon removal the faces had seen multiple cheap smart repairs and at some point some full refurbishments where they had taken the life out of the wheel. Diamond cut wheels are a challenge when it comes to refurbishment if you don't know what your doing, they are extremely easy to mess up and these wheels are prime examples of wheels that have been poorly refurbished time after time. The result of this was that they were not perfect when they returned. The reason being is because so much had been taken from the face of the wheels during previous refurbishments that my wheel guy had very little alloy left to work with making it extremely difficult to get the perfect finish with clean lines between the contrasting diamond cut and black. The client was kept informed throughout and both myself and my wheel guy did all that we could to ensure he was satisfied with the end result but it goes to show you really don't know what your buying until it's in the hands of a professional.

This detail was a challenge from start to finish. I enjoyed every minute of it and in some areas it was a learning curve but I take positives from that and it only makes me a better detailer. The outcome was stunning and was the result of over 100 hours detailing. This doesn't come cheap but when your looking for the level of finish I achieved with the additional touches of wheels and coatings you would be a fool to pay an amateur.

Thats enough of my waffle and time to let the photos do the talking...